Electric motors are the backbone of industrial production. In markets such as Brazil, India, and Southeast Asia, the demand for high-efficiency motors continues to grow due to expansion in manufacturing, mining, and energy sectors. According to the International Energy Agency (IEA), electric motors account for nearly 45% of global electricity consumption in industries. One of the most critical factors that ensures motor reliability and lifespan is winding insulation.

However, winding insulation problems remain one of the top three causes of motor failure worldwide. Research from IEEE indicates that up to 30–40% of motor breakdowns are related to insulation failure. For B2B buyers and procurement managers, understanding these issues and their solutions is vital when sourcing motors or related insulation materials.

1. Common Problems in Motor Winding Insulation

a) Thermal Aging

Cause: Continuous exposure to high operating temperatures degrades the insulating material.

Impact: Loss of dielectric strength, cracks, and eventual short circuits.

Data Point: Every 10°C rise in operating temperature can reduce insulation life by 50% (Arrhenius rule for insulation aging).

b) Electrical Stress

Cause: Overvoltage, surge, and partial discharges.

Impact: Localized breakdown of insulation layers.

Common in: Motors used with variable frequency drives (VFDs).

c) Mechanical Damage

Cause: Vibration, improper winding tension, or poor handling during assembly.

Impact: Insulation layers get cut or abraded, leading to early failures.

d) Moisture and Contamination

Cause: Humid climates, dust, chemical vapors.

Impact: Reduction of insulation resistance, leakage currents, corrosion.

Brazil relevance: Many regions have high humidity (>70%), which accelerates this problem.

e) Partial Discharge and Corona Effect

Cause: High voltage stress in medium and high-voltage motors.

Impact: Erosion of insulation surface, leading to pinholes and cracks.

2. How to Avoid These Problems

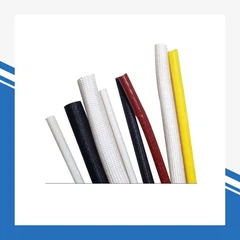

a) Choose the Right Insulation Material

Use mica tape, polyester film, aramid paper, or epoxy glass laminates depending on voltage and thermal class.

For humid markets like Brazil, hydrophobic coatings and moisture-resistant tapes are essential.

b) Maintain Proper Temperature Control

Ensure motors operate within their rated thermal class (Class F = 155°C, Class H = 180°C).

Apply thermostats or temperature sensors for real-time monitoring.

c) Improve Winding Process Quality

Maintain uniform winding tension.

Use automated winding and taping systems to reduce manual defects.

Apply vacuum pressure impregnation (VPI) to eliminate air pockets and strengthen insulation bonding.

d) Regular Testing and Maintenance

Insulation resistance test (IR): Should be 100 MΩ or higher for low-voltage motors.

Partial discharge test: Recommended for medium-voltage motors.

Dielectric strength test: Ensures insulation withstands rated voltages.

e) Protection Against Environment

Use sealed enclosures or anti-corrosion varnish in coastal or chemical environments.

Apply UV-resistant coatings for outdoor motors.

3. Why This Matters for Procurement Managers

For B2B buyers, especially in new emerging markets, the total cost of ownership (TCO) matters more than just purchase price. A study by EASA shows that unplanned downtime caused by motor failure can cost 10–20 times the price of the motor itself. By ensuring high-quality insulation, companies can:

Reduce unplanned shutdowns.

Increase motor service life by 30–50%.

Lower maintenance and replacement costs.

4. How We Support Global Buyers

As a supplier of transformer and motor insulation materials, we help our clients in Brazil, Southeast Asia, and beyond to:

Select the best-fit insulation materials based on application and voltage.

Provide customized solutions for high humidity, high temperature, or high voltage environments.

Offer technical guidance and quality certification to ensure compliance with IEC and ASTM standards.

Our experience in B2B industrial supply chains ensures that procurement managers not only source materials but also gain a reliable technical partner for long-term cooperation.

Conclusion

Motor winding insulation is not just a technical detail - it is a business-critical factor that determines reliability, operating costs, and competitiveness. By understanding the common problems and implementing preventive measures, companies can avoid expensive breakdowns and achieve stable production.

If you are looking for reliable motor insulation materials or need customized solutions for your projects in Brazil or other markets, feel free to contact our team. We are ready to support your business growth with quality products and technical expertise.