Products Description

YD 200AL, is heat-resistant polyester enameled coated aluminum wire belonging in high temperature (200°C) thermal class, able to be manufactured in the diameter range of 0.20 – 4.00 mm.

Customized services

Enameled coated aluminum wire diameter customization: Products of different wire diameters are provided according to customer needs.

Customized insulating paint: Provide insulating paint of different thicknesses and colors.

Packaging customization: Supports different packaging methods such as roll packaging and tray packaging (usually film + wooden box + pallet) to meet transportation and storage needs.

Quality Certification and Standards

- Passed UL, RoHS, REACH, ISO9001 certification

- Comply with IEC 60317, NEMA MW 1000 standards

Our strength

1. Fast delivery capability: We have efficient production lines and logistics systems to ensure fast delivery.

2. Advantages appreciated by cooperative customers:

High cost performance: Aluminum wire is cheaper than copper wire and is suitable for large-volume purchases.

Lightweight: Reduce product weight and reduce transportation costs.

Environmental protection: Comply with international environmental protection standards and meet export requirements.

Application

1.Refractory transformer

2.Hermetic machine

3.Motors of the power tool

4.Voltage regulators

5.Various types of magnet-coils

6.General purpose electric motors

parameters

|

Thermal Class (°C) |

Class C, 200 °C |

|

Insulation | Base Coat |

Polyester-imide |

|

Insulation | Top Coat |

Polyamide Imide |

|

Insulation | Bong Coat |

- |

|

Production Range (MM) (MM) |

0.20 - 4.00 mm |

|

Certification I.E.C |

IEC 60317 - 25 |

|

UL File No. |

- |

|

Class Temperature (°C) |

200 °C |

|

Heat Shock (°C) |

≥ 220 °C |

|

Cut Through Temperature (°C) |

≥ 320 °C |

|

Solderability (°C) |

Non solderability |

|

Bonding Temperature (°C) |

Not Applicable |

|

Re-softening Temperature (°C) |

Not Applicable |

|

Normal Solvent Resistance |

≥H |

factory display

company advantage

1.Capital advantage

With a healthy financial position and excellent asset quality, it can attract capital through banks, bonds, equity financing and other forms, and has good resource acquisition advantages.Introduction

2.Scale advantage

The production capacity ranks among the best in the industry, with strong supply guarantee capabilities and high market share.

3.Variety advantage

All leading products are serialized, with complete varieties and specifications, and wide application fields. We can develop special varieties according to market and user needs.

4.Market Advantage

It has an advanced sales team and sales network system in the industry, with excellent dealers and large customer resources. It has established a domestic sales network that focuses on product application and focuses on various professional areas, radiating the national market and covering Europe, America, Asia and Africa. overseas marketing network.

fAQ

Q1: Why choose aluminum wire instead of copper wire?

A: We also produce enameled copper wire. The price of copper wire will be higher. Compared with copper wire, aluminum wire is lighter and more cost-effective. It is especially suitable for equipment that pursues lightweight design.

Q2: Do you provide quality inspection reports?

A: Yes, each batch of products comes with performance test reports such as conductivity, withstand voltage, and thickness uniformity.

Q3: Does it support customizing different wire diameters and temperature levels?

A: Yes, we support customization of multiple wire diameters and insulation levels.

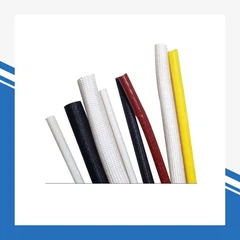

Hot Tags: enameled coated aluminum wire, China enameled coated aluminum wire suppliers, automotive service application of transformer winding, winding fixture for transformer, cost effective insulation paper, rubber insulation sleeve, pvc insulation sleeve, industrial insulation paper