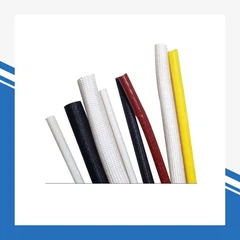

Products Description

PE heat shrink tubing is a tubular insulation material with a shape memory function, modified by electron beam irradiation based on cross-linked polyethylene (XLPE), which complies with UL 224. The standard shrinkage ratio is 2:1 to 4:1, and the operating temperature range is -55°C to 125°C (UL heat aging test passed).

| Type | Key Parameters | Application Scenarios |

|---|---|---|

| General Type | Shrinkage ratio: 2:1, Wall thickness: 0.4 mm | Protection for wire harness bundling |

| High-magnification Type | Shrinkage ratio: 4:1, Tear resistance: ≥ 20 N/mm | Coating for special-shaped parts |

| Flame-retardant Type | UL 94 V-0 certification, Limiting oxygen index: ≥ 30% | Battery packs of new energy vehicles |

| Color Marking Type | Customized according to the RAL color card, Weather resistance level: 5 | Line marking for industrial equipment |

,

Product customization capabilities:

Product diameter range: Φ2mm-Φ200mm

Product special features: UV resistance (QUV test 3000 hours ΔE < 2)

Printing service: LOGO/warning logo can be printed on the product surface (friction resistance test > 500 times)

Compared with other shrink sleeves

| Index | PE Heat Shrinkable Tube | PVC Heat Shrinkable Tube | POF Heat Shrinkable Tube |

|---|---|---|---|

| Environmental Friendliness | Halogen-free and non-toxic | Contains vinyl chloride | Biodegradable |

| Temperature Resistance | -55~125℃ | -40~105℃ | -50~90℃ |

| Shrinkage Rate | Up to 4:1 | 2:1 | 3:1 |

| Cost | ¥0.8-2.5/m | ¥0.5-1.8/m | ¥1.2-3.0/m |

certificate

exhibition

Display

PE heat shrink tubing parameters

Application

About us

1. Manufacturer Place your order directly to the factory, no intermediate cost, more fast delivery ,better service and economical cost.

2. Strict QC inspection Good quality is top important during cooperation. We will make QC inspection strictly before ship out to make sure every piece stayed in a good condition. If any problems made by us after you received cases then we will full responsible to compensate you.

3. Stable Supply As a manufacturer with strong ability ,we have enough stock to meet your needs.

4. Fast delivery Enough stock in the warehouse, normal order can be delivery in 20-30days.

Factory Display

fAQ

- Question: What are the shrink ratios of the heat-shrinkable sleeves?

Answer: We offer 2:1, 3:1 and 4:1. The 2:1 (customizable) has a high fitting degree and a small change in size. The 4:1 has a wide range of adaptability and is suitable for different objects.

- Question: What is the shrink temperature range of the heat-shrinkable sleeves?

Answer: It's between 80 - 120°C (It varies for different materials and can be customized). Within this range, the heat-shrinkable sleeves will shrink evenly and quickly. Common heating equipment can be used and there will be no charring or deformation.

- Question: What are the maximum and minimum working temperatures of the heat-shrinkable sleeves?

Answer: The maximum is approximately 105°C. Under high temperatures, it has good mechanical and insulation properties. The minimum is - 55°C. It won't become brittle in cold environments and can be used for protection in outdoor settings, automotive wire harnesses and so on.

- Question: What are the standard inner diameters and wall thicknesses of the heat-shrinkable sleeves?

Answer: There are various inner diameters, such as 3mm, 6mm, 10mm, etc. The wall thicknesses include 0.5mm, 1mm, 1.5mm (customizable), etc. Thin walls are used in compact spaces, while thick walls are used in high-voltage or scenarios that require high mechanical strength.

Hot Tags: pe heat shrink tubing, China pe heat shrink tubing suppliers, electrical insulation sleeve, dielectric insulation paper, silicone insulation sleeve, aerospace insulation sleeve, residential insulation sleeve